News from Research & Development

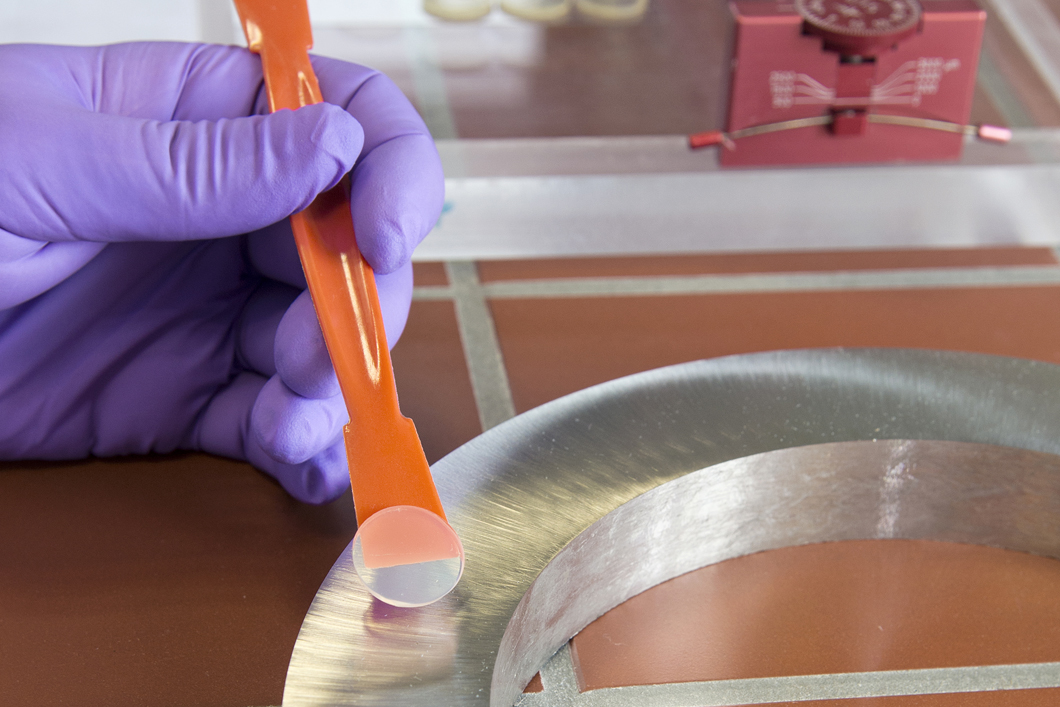

Picture: Bundesamt für Materialforschung und -prüfung

BAM certifies: Stainless steel cleaning with Reuter systems prevents rust

July 2023 | Stainless steels are coated with a layer of chromium oxide that is only a few atoms thick. This so-called passive layer protects the metal from corrosion. If there are weak spots in the passive layer after the steel has been processed, unwanted corrosion will occur. This not only looks ugly, but can also cause safety-related damage.

When cleaning with carbon fiber brush and electrolytes from Reuter, the passive layer is restored during the cleaning process, still in the same operation. The surface is therefore immediately 100% protected against renewed corrosion. This is now also certified by the BAM (Federal Office for Materials Research and Testing in Berlin) after an extensive series of tests.

By the way: The corrosion test using KorroPads will be available from us shortly.

Innovation, promoted by the government

May 2022 | The German Federal Ministry for Economic Affairs and Climate Protection also sees that we have many good ideas. As part of the Central Innovation Programme for SMEs (ZIM), our research projects receive government funding. Thank you!

Electrolytes for Cleaning & Polishing

Brand new outfit for our Electrolytes

February 2020 | We have now given our electrolytes a new outfit: super-tight bottles and canisters with UN hazardous goods approval, indestructible, in fashionable Reuter orange. And because the new bottling plant is working so fast, there are even real price advantages – look out for the inexpensive new packaging units.

Download: Electrolytes for Cleaning and Polishing PDF (0,7MB) »

10 years of Innovation & Quality

Wow – that was really 10 years only? A lot has happened…

For our round birthday we have laced a beautiful bundle:

16 pages of innovation & jubilee prizes!

The new AutoFeed:

The first automatic electrolyte supply system

Significantly faster working. Reduced fluid consumption.

Compatible with any cleaning device on the market.

The new Performance Brush:

That’s how innovation works!

performance enhancement and cost-effectiveness.

Preview 2019:

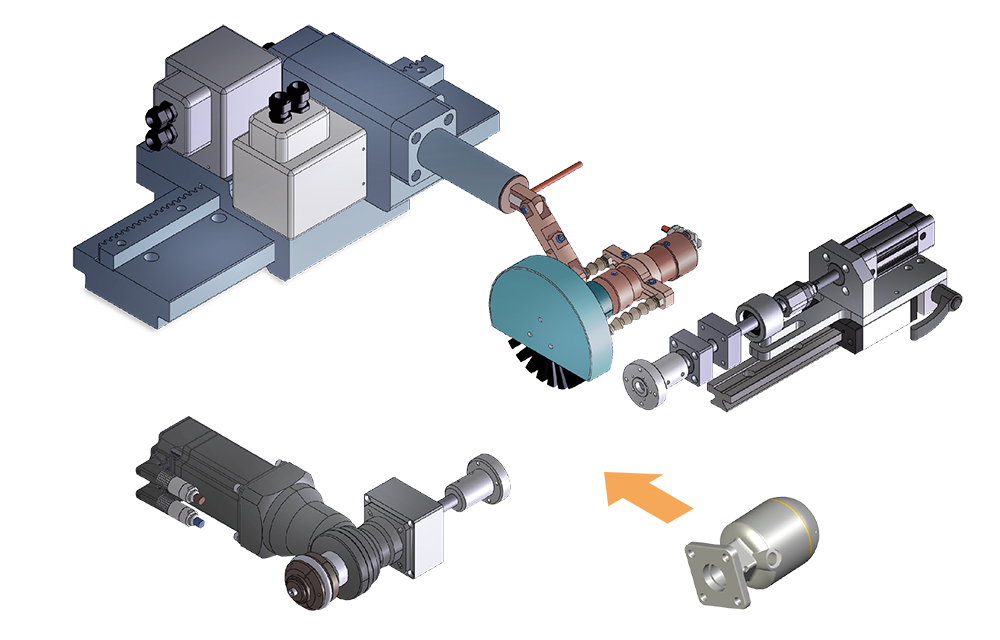

The AutoCleanox 4.0

cleans, polishes, passivates, rinses & drys fully automatic in one operation

with up to 75% time and cost savings

- Full automation with up to 4 CNC axes

- CNC control with program memory and can-bus interface

- patented electromechanical brush drive

- patented high-performance electrolyte intelligent feeding

- automatic rinsing and drying program

- integrated exhaust system with condensate and carbon filter